Block EDM

(Electrical Discharge Machining)

Electrical discharge machining (EDM) in this case also utilizes electrical discharges for material removal. Unlike wire EDM, where contours are cut using a wire, here a pre-machined surface is copied onto the workpiece. EDM typically involves a slower process and the cost is increased due to the constant need for custom electrode manufacturing.

CNC MILLING

high-quality CNC machining centers

We have equipped ourselves with high-quality CNC machining centers capable of simultaneous 3 and 4-axis milling. These centers ensure impeccable quality and provide perfect surface finishes on workpieces. Our machining centers are supported by CAM systems to create complex shapes efficiently.

Technology

Wire Electrical Discharge Machining

The process can be described simply as cutting any contour passing through the workpiece using a brass wire, provided that the workpiece conducts electricity. In tool and part manufacturing, there is an increasing need to create surfaces and shapes on workpieces with specific dimensional tolerances and surface roughness, achievable only through wire EDM technology. The majority of our machinery utilizes this technology, as it is the most effective method for machining high-wear-resistant materials such as hardened steel and carbide.

Technology

Center

drilling

Mostly used for creating the starter hole for wire EDM machines.

It is also an EDM machine, where a brass tube is the tool. It is suitable for making holes ranging from 0.2 to 2.0 mm in diameter. In other cases, it is excellent for creating coolant holes, for example, for producing a 1x300 mm diameter, which is impossible to achieve through traditional mechanical machining methods.

Technology

CNC profile grinding

The surface finish, structure, and dimensional tolerances of certain tools necessitate grinding. For carbide materials, this is done using diamond tools. We offer CNC profile grinding services for both cylindrical and block-shaped workpieces.

Technology

Wire Electrical Discharge Machining

The process can be described simply as cutting any contour passing through the workpiece using a brass wire, provided that the workpiece conducts electricity. In tool and part manufacturing, there is an increasing need to create surfaces and shapes on workpieces with specific dimensional tolerances and surface roughness, achievable only through wire EDM technology. The majority of our machinery utilizes this technology, as it is the most effective method for machining high-wear-resistant materials such as hardened steel and carbide.

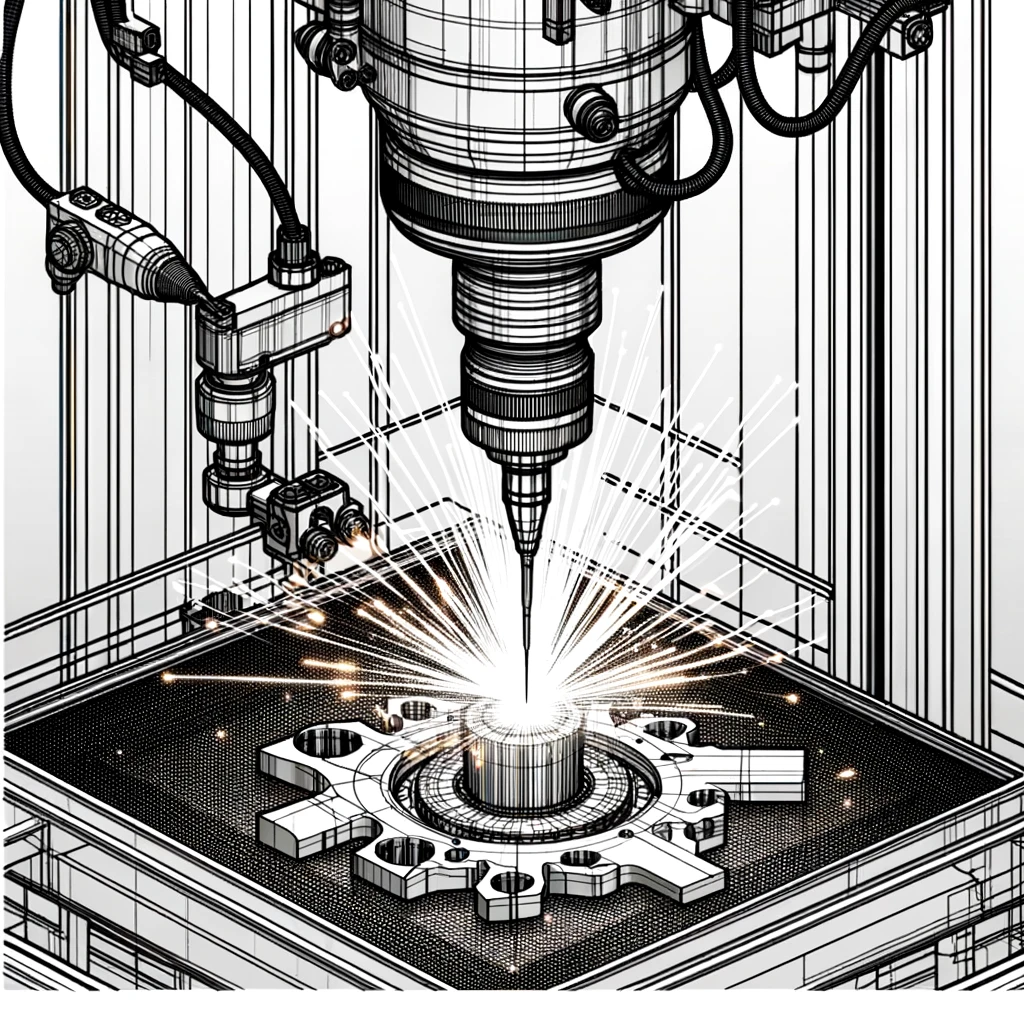

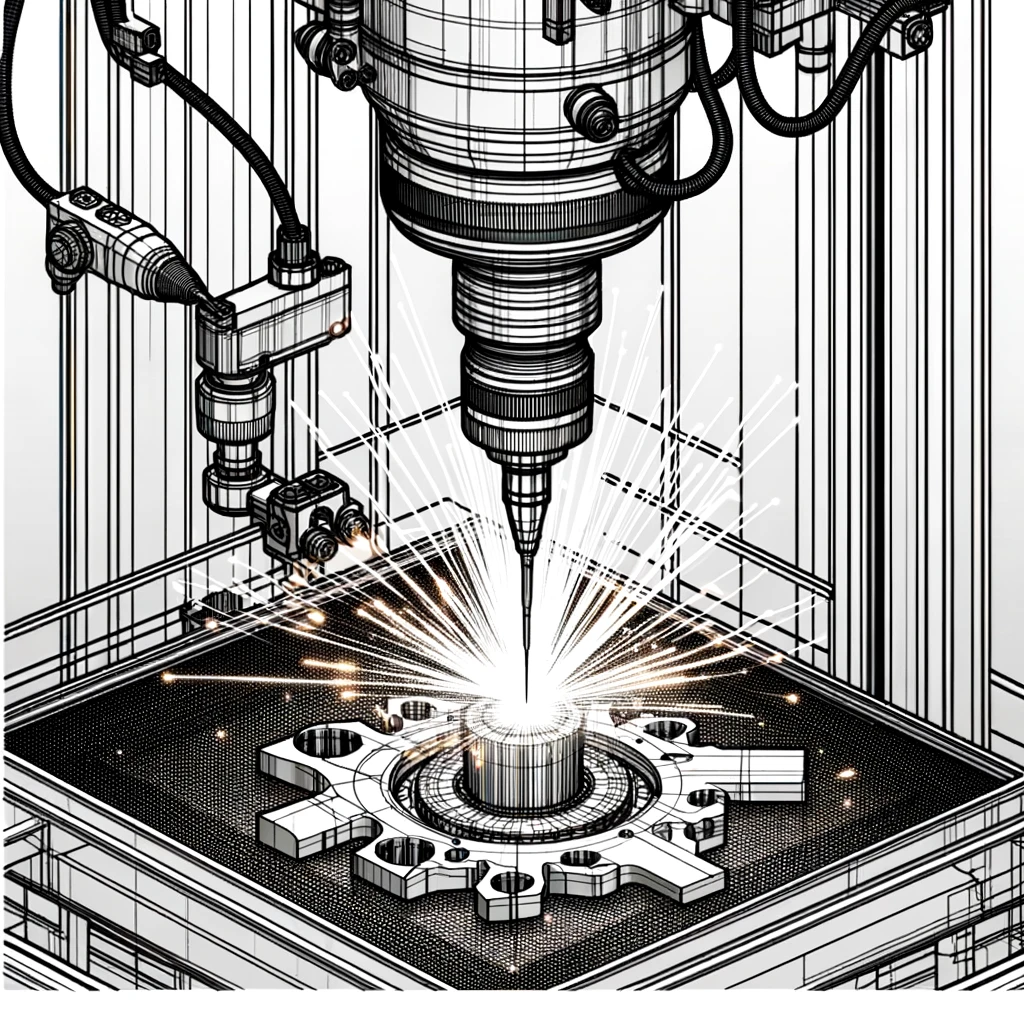

Block EDM

(Electrical Discharge Machining)

Electrical discharge machining (EDM) in this case also utilizes electrical discharges for material removal. Unlike wire EDM, where contours are cut using a wire, here a pre-machined surface is copied onto the workpiece. EDM typically involves a slower process and the cost is increased due to the constant need for custom electrode manufacturing.

Technology

Center

drilling

Mostly used for creating the starter hole for wire EDM machines.

It is also an EDM machine, where a brass tube is the tool. It is suitable for making holes ranging from 0.2 to 2.0 mm in diameter. In other cases, it is excellent for creating coolant holes, for example, for producing a 1x300 mm diameter, which is impossible to achieve through traditional mechanical machining methods.

CNC MILLING

high-quality CNC machining centers

We have equipped ourselves with high-quality CNC machining centers capable of simultaneous 3 and 4-axis milling. These centers ensure impeccable quality and provide perfect surface finishes on workpieces. Our machining centers are supported by CAM systems to create complex shapes efficiently.

Technology

CNC profile grinding

The surface finish, structure, and dimensional tolerances of certain tools necessitate grinding. For carbide materials, this is done using diamond tools. We offer CNC profile grinding services for both cylindrical and block-shaped workpieces.

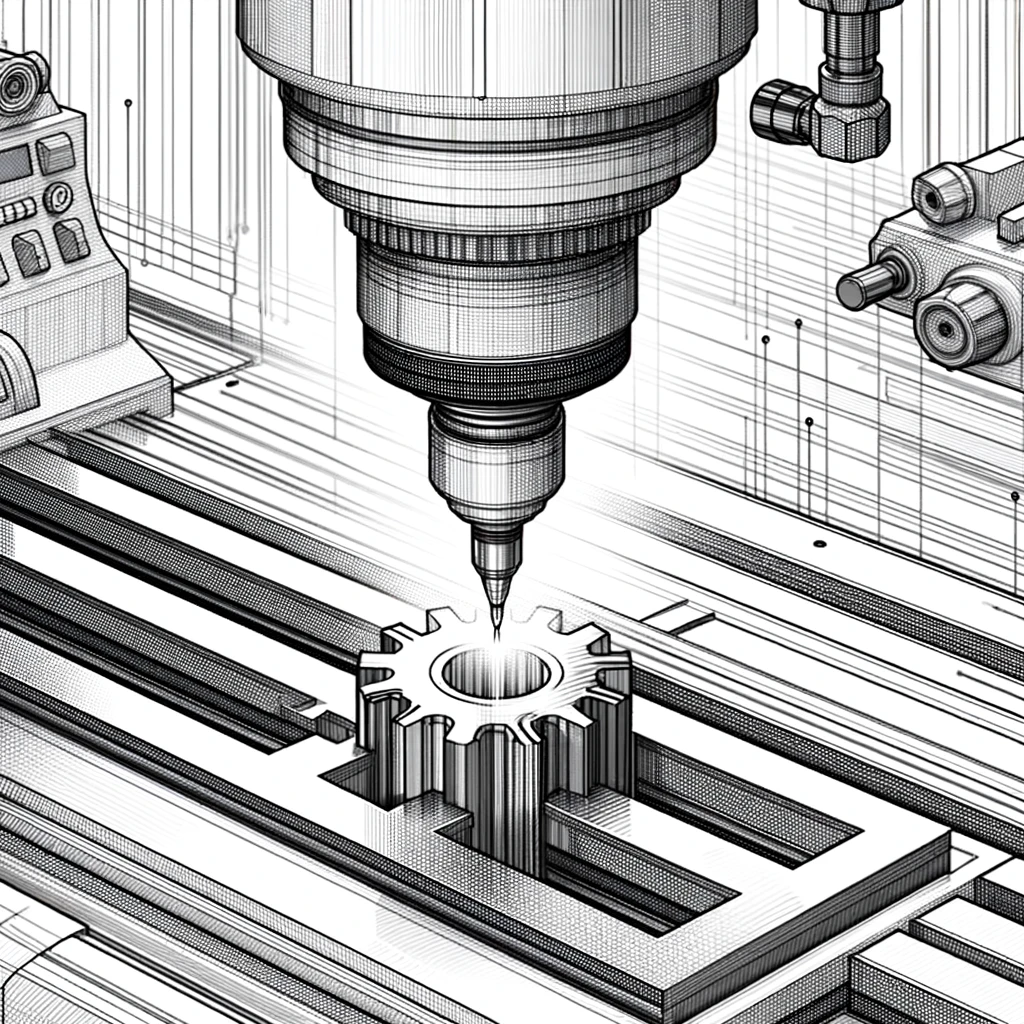

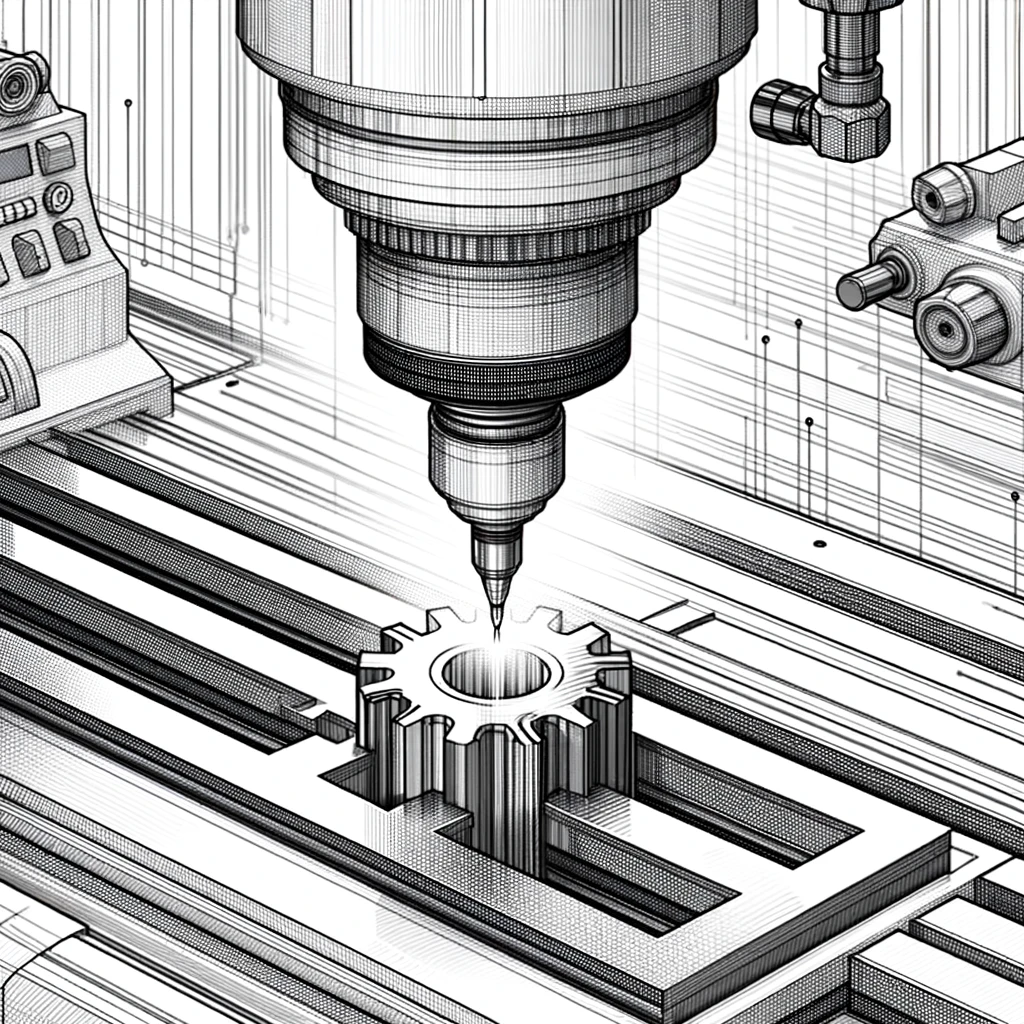

WIRE ELECTRICAL DISCHARGE MACHINING

The process can be described simply as cutting any contour passing through the workpiece using a brass wire, provided that the workpiece conducts electricity. In tool and part manufacturing, there is an increasing need to create surfaces and shapes on workpieces with specific dimensional tolerances and surface roughness, achievable only through wire EDM technology. The majority of our machinery utilizes this technology, as it is the most effective method for machining high-wear-resistant materials such as hardened steel and carbide.

BLOCK EDM (ELECTRICAL DISCHARGE MACHINING)

Electrical discharge machining (EDM) in this case also utilizes electrical discharges for material removal. Unlike wire EDM, where contours are cut using a wire, here a pre-machined surface is copied onto the workpiece. EDM typically involves a slower process and the cost is increased due to the constant need for custom electrode manufacturing.

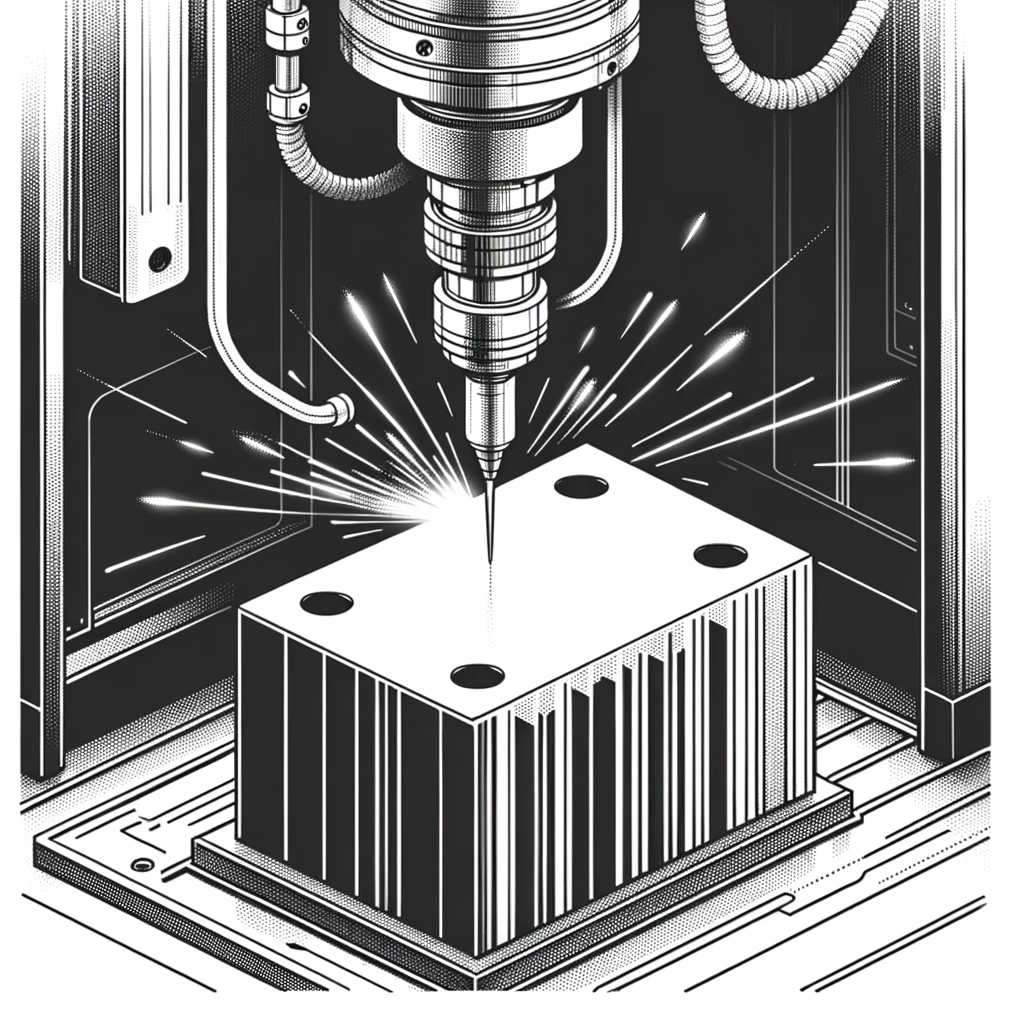

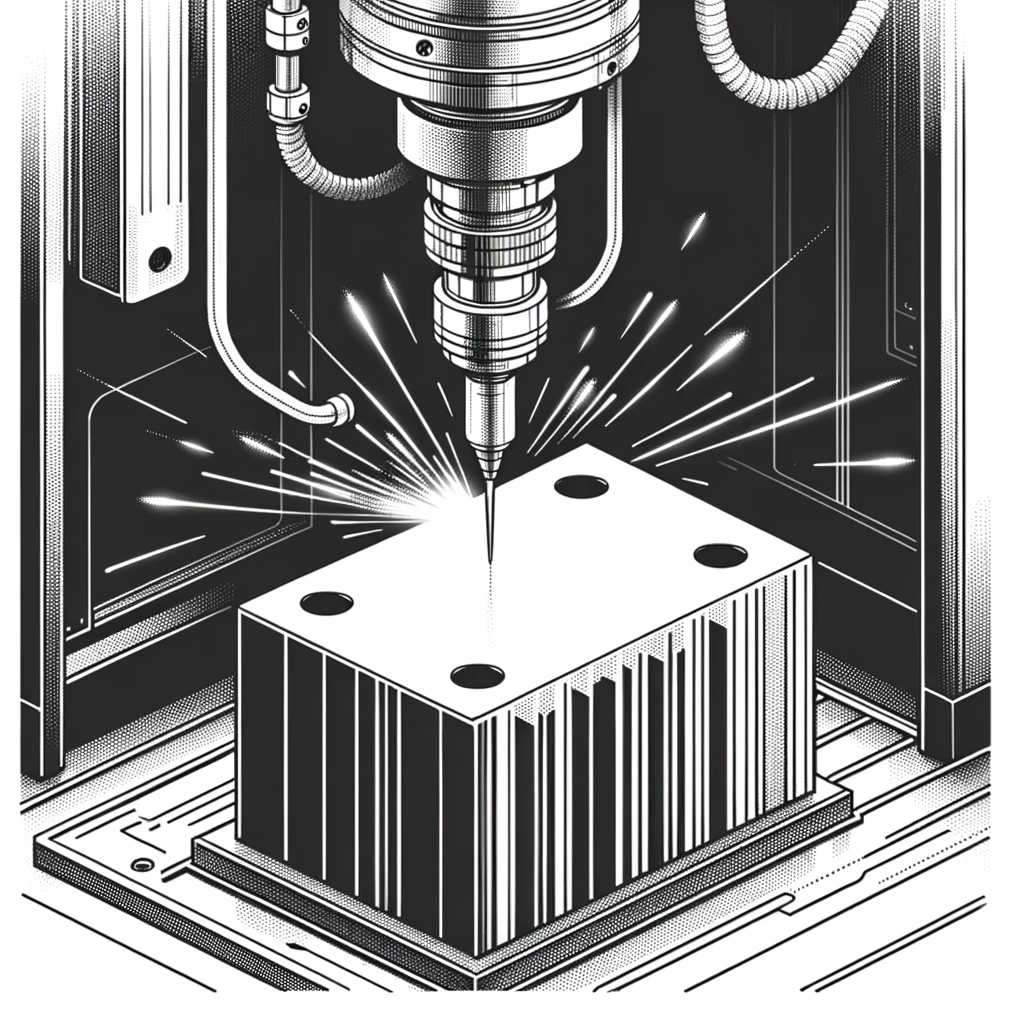

CENTER DRILLING

Mostly used for creating the starter hole for wire EDM machines.

It is also an EDM machine, where a brass tube is the tool. It is suitable for making holes ranging from 0.2 to 2.0 mm in diameter. In other cases, it is excellent for creating coolant holes, for example, for producing a 1×300 mm diameter, which is impossible to achieve through traditional mechanical machining methods.

CNC MILLING

HIGH-QUALITY CNC MACHINING CENTERS

We have equipped ourselves with high-quality CNC machining centers capable of simultaneous 3 and 4-axis milling. These centers ensure impeccable quality and provide perfect surface finishes on workpieces. Our machining centers are supported by CAM systems to create complex shapes efficiently.

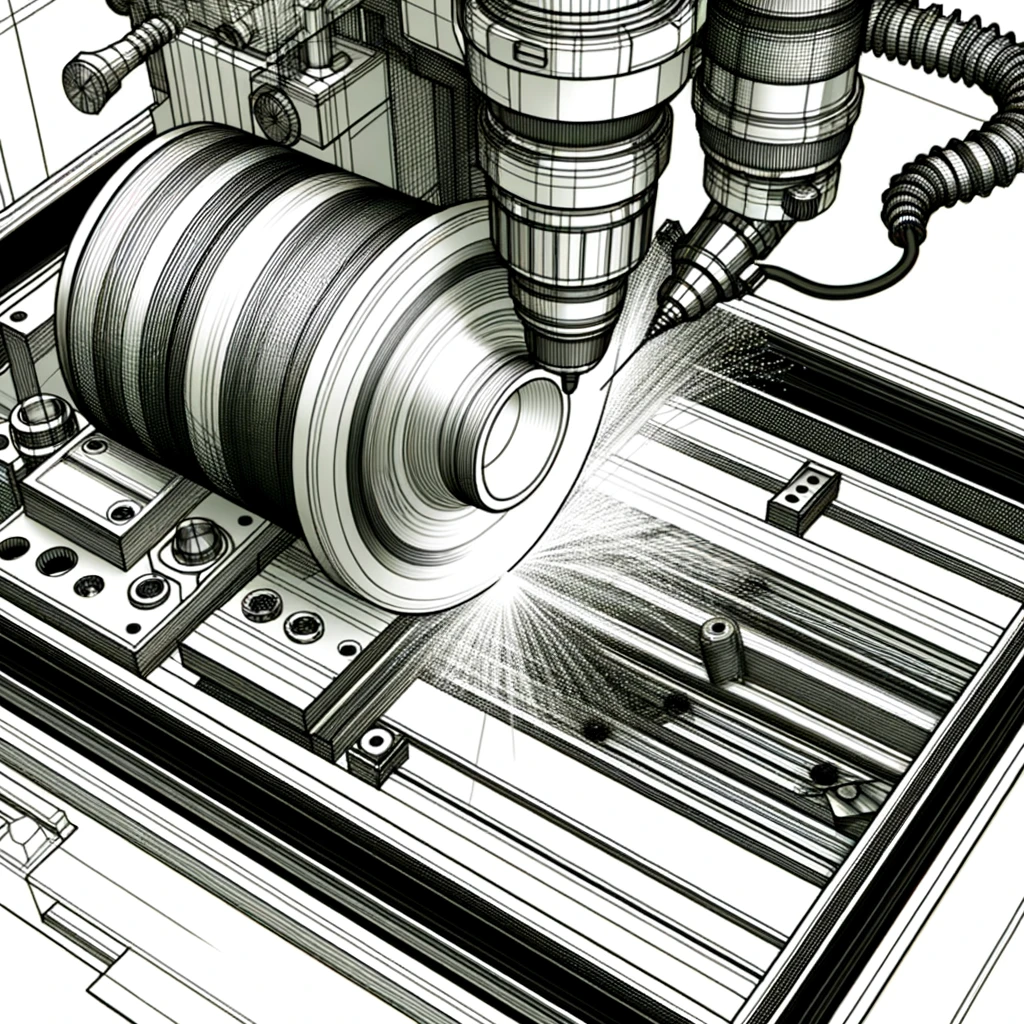

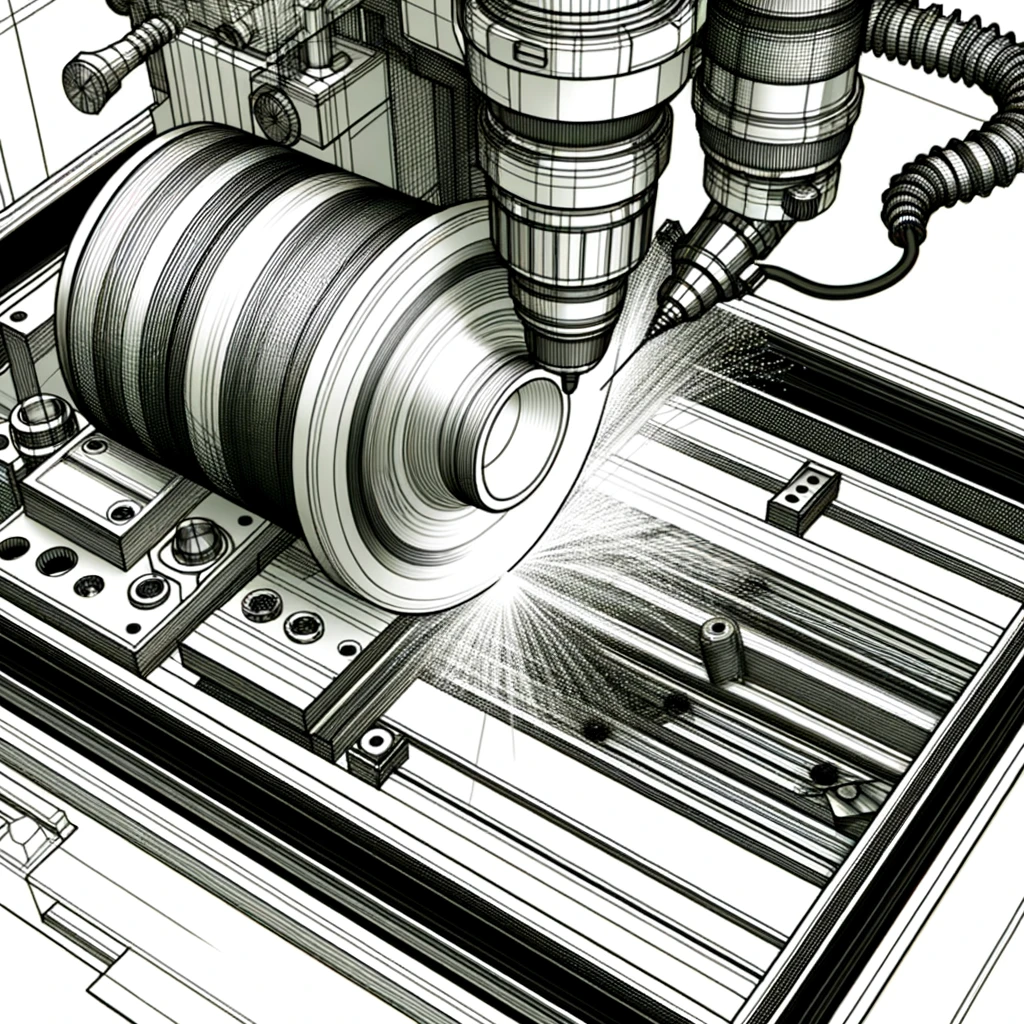

CNC PROFILE GRINDING

The surface finish, structure, and dimensional tolerances of certain tools necessitate grinding. For carbide materials, this is done using diamond tools. We offer CNC profile grinding services for both cylindrical and block-shaped workpieces.